Engineered to meet the highest standards: yours

Two Striper®, from Abrasive Technology, is the original brazed diamond dental bur. Invented over 40 years ago, our proprietary P.B.S.® brazing process is still recognized as the best bonding system in the industry. This innovative process uses a nickel chrome alloy to chemically adhere each individual crystal to a one-piece, hardened, stainless steel blank, creating a permanent bond between the diamond layer and the substrate and greatly extending the working life of the tool with no stripping or peeling.

Better diamonds

We start with better diamonds

The quality of dental diamond instruments starts with the quality of the diamond crystals themselves. And with Two Striper®, the difference is crystal clear. We use natural, virgin diamond crystals — which have more corners and angles than synthetics — for superior abrasion. The individual crystals are selected by exact size and shape to ensure high diamond exposure and a uniform cutting surface.

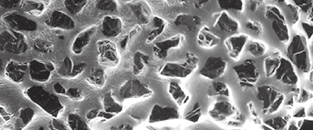

Slide to view Two Striper®’s diamond versus our competitor’s

The meticulously selected diamond crystals engineered into each Two Striper® bur provide little variation in size, allowing for a faster, more consistent cut.

Better design

We engineer better design

Our superior engineering process enables us to optimally distribute and space our diamonds to create a uniform cutting surface that reduces heat, chatter and vibrational trauma, while inhibiting clogging by naturally allowing space for debris to exit the worksite. Our unique approach minimizes unwanted high and low spots, practically eliminating the peaks that prevent dentists from using the full surface of the bur.

FIGURE 1a

Two Striper®’s design creates natural irrigation channels that allow for the flushing of water and cutting debris while also ensuring even more crystals touch the surface of the tooth

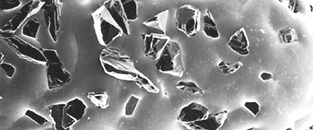

FIGURE 1b

The tightly packed crystals in competitors’ burs trap debris, clogging up the surface of the bur, and also further inhibit lower crystals from contacting the tooth’s surface

Smoother surface

We create a smoother surface

With the combination of our meticulous natural virgin diamond selection and superior engineering, Two Striper® burs provide an uncommonly smooth surface finish. Not only does this result in greater customer satisfaction, it can eliminate the need for dentists to use a second pass over a crown with a finer grit diamond to smooth out the surface—reducing both prep time and cost.

FIGURE 2a

View of tooth cut with a Two Striper® bur, allowing for a smoother surface finish

FIGURE 2b

View of a tooth cut with a competitor’s bur, showing a rougher surface finish

Better results

We deliver better results

Because dentists operate in confined spaces, feel is just as important as sight. And while it’s difficult to measure “feel,” vibration, skipping and bur chatter creates a rougher feeling cut than desired. Two Striper® burs just feel right, carefully crafted to create a more consistent surface for each bur that reduces unwanted vibration and allows for a smoother surface finish. The result is a better solution for dental professionals all the way around.

More comfortable, consistent feel

Faster, cooler and longer cuts

Improved prep surface quality

Bond doesn’t strip or peel

Multiple uses from a single bur